drive shaft coupling failure

Quote Reply Topic. β 1 β 2 The maximum joint operating angles depends upon the.

About Shaft Couplings Nbk The Motion Control Components

The first 90 percent of the code accounts for the first 90 percent of the development time.

. Flexible Shaft Couplings can help prevent these issues by transmitting torque while compensating for parallel angular and axial misalignment between drive components. The remaining 10 percent of the code accounts for the other 90 percent of the development time. The failure may be coursed by improper installation excessive misalignment and poor coupling selection and so on.

Each section weighs approximately 3 kg. Symptoms of Bad Drive Shaft Vibration Knocking noise Squeaking noise U-joint motion Turning issues. The shaft couplings will also need to be undone for the same reason.

Shaft failure maintenance techniques Conveyor heavy nip roller. The objective of this paper is to study various shafts failure analysis and select the best method to find out the root cause failure of heavy nip roller shaft used in textile industry. Selecting the wrong type of coupling for the application Several criteria must be considered when deciding on a type.

2 Abnormal wear caused by lack of lubricant packed in coupling. The two mating surfaces of the coupling. β 1 β 2 Angular Misalignment ß1 ß2 The driver and driven shaft centerlines of your equipment must intersect at the center of the drive shaft.

TRC Jaw and MC couplings will continue to drive for a period of time after element failure. December-31-2021 at 1133am So while out on the lake late yesterday pulling kids on a tube - in my defense it was windy I started noticing a pronounced vibration from the drive train and not long after that a clunk from something breaking and an immediate loss of power. Investigation of our failure found shaft to engine alignment very good only 0001 misalignment on a 3 inch coupling no indication of bent shaft and no indication of bearing wear or seal failure in the transmission.

Failure Criteria This is very relevant to ductile metals. Covers that are mounted over the couplings see Exhibit 2 rotate with the couplings as the drive shaft tums to operate the Cover-Shield Failure and Falling Incident at R. Positive Vs Non-Positive Drive In the event of tyre failure on the Optiflex Tyre coupling there is no connection between the drive and driven shaft.

12 Reasons for coupling failure and how to avoid them 1. At Crane Engineering we find the root cause of coupling failure ladders up to one of the following reasons. Put in a new Dorman one and it has destroyed itself in just 2 months.

If the shaft is to be removed the gearbox oil will need to be drained first. 1 Normal torsional pulses generated as the impeller climbs over the pump cam. Either that or the u-joint itself is not stable.

It is conservative and relatively easy to apply. The gearbox is unbolted and supported as it is moved clear and can then be lifted clear for inspection on a bench. The entire drive shaft and coupling assembly was replaced including the u-joints at each end.

The cap seals of the bearings could have rust on them. It assumes that failure occurs when a maximum shear stress attains a certain value. The drive shaft was implemented.

Drive shaft failure Posted. Selecting the coupling too late in the design process Couplings are often selected extremely late in the application. Assuming the shaft is made from a ductile material the failure criteria applicable is the Maximum Shear Stress Theory MSST criteria.

If the cushioned plate option is followed this is not necessary. Discussion Starter 1 Feb 7 2015. Driveshaft Coupling Failure.

The crane was rated at 10 tons with a span of 205 m and handled about 100. Up to 50 of damage to rotating equipment is directly related to misalignment. If the U-joint of your drive shaft rotates too fast or fails to rotate then its a problem with your drive shaft.

Hefty thickeners which have no lubrication characteristics accumulate in the gear tooth mesh area resulting in premature coupling failure. Jump to Latest Follow 1 - 14 of 14 Posts. Misalignment can be caused by improper installation of the pump and motor pipe strain even bent shafts.

The Two-Shaft raw water pump shaft couplings will wear and fail due to. Saunders Hydroelectric Generating Station Abridged The coupling covers are made up of two sections. From direct drive to magnetic coupling.

Joined Apr 20 2007 697 Posts. In order to improve coupling service life. Youll need to have your drive shaft replaced because you cant drive your vehicle in this condition.

Foot of joint coupling measured joint center to joint center distance B is equivalent to approximately ½ to 1. Although you may do quite well on the maintenance of couplings they can still fail sometimes. The failure of this shaft originated at the intersection of two stress raisers the change in the shaft diameter and keyway.

Yes its been a long while since I last posted but only because building this boat is taking forever Although the. The highest vibration level dropped from 24 mms pk at the gearbox horizontal measurement locationnear the input shaft to 78 mms pk after change to a flexible coupling. Shaft misalignment can limit a machines performance cause excessive vibration high reaction loads and accelerated wear and often leads to premature equipment failure.

Had to replace my factory rear driveshaft coupling recently has a few small cracks due to age. Optiflex can be used as a shear-pin but never in a situation where the drive should always be maintained. Gear Coupling Grease is built to highly resistant to centrifugal separation with the oil and thickener which makes it possible for the lubricant to get employed for any reasonably prolonged time period of.

Shaft failure causes the unnecessary shutdowns and leads to heavy production loss. Failure of overhead crane drive shaft In Steelworks Split the high-speed electric overhead crane Fig1 was suitable for transport of the billets from the melt shop to the rolling mill hall. 3 Early failure of the short-lived shaft bearings from age and use.

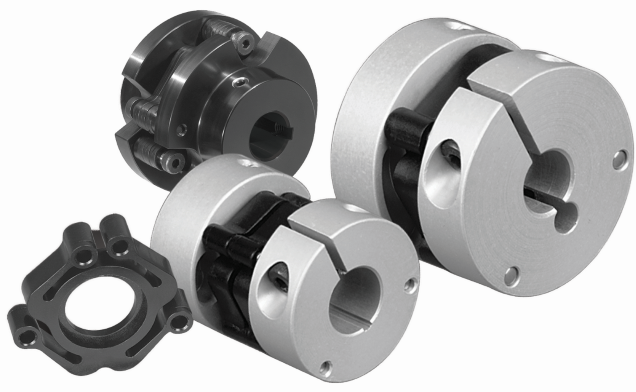

Control Flex Shaft Couplings Flexible Shaft Couplings

Pdf Analysis Of Ship Shaft Line Coupling Bolts Failure

What Is A Coupling How Does A Shaft Coupling Work Types Of Shaft Coupling

Laser Alignment On Site Laser Alignment Of Pumps And Motors Gear Units And Fans Coupling Misalignment Is One Of The Most Fr Alignment Electric Motor Mechanic

About Shaft Couplings Nbk The Motion Control Components

Mechanical Power Transmission Training Mechanical Power Power Transmission

Gear Coupling Tutorial Part Ii Configurations Coupling Answers Where The World Turns For Coupling Knowledge

Causes For Pump Coupling Failures How To Avoid Them Sintech Pumps

Shaft Coupling Definition Types Uses Working Principle Advantages Complete Guide Engineering Learn

12 Reasons For Coupling Failure And How To Avoid Them Insight Acorn Industrial Services Ltd

Choosing A Reliable Conveyor Chain For Your Application In 2021 Conveyor Chain Broken Chain

Parallel Misalignment Or Offset Top And Angular Misalignment Bottom Fire Protection System Mechanical Engineering Design Alignment

Flexible Shaft Coupling Bc Series Oep Couplings Sleeve And Shear Pin

Damaged Rubber Part Of Flexible Coupling Installed Between Main Engine Download Scientific Diagram

Flexible Shaft Couplings For High Temperature Applications

About Shaft Couplings Nbk The Motion Control Components